Welcome back to another exciting year with IMC's monthly FAQ series! This month, we’re diving into some of the most frequently asked questions about floor trough grating. Whether you're looking for practical tips or want to understand the differences between various materials and designs, we’ve got you covered. Let’s get started!

First up, let’s talk about the two most popular choices for floor trough grating: stainless steel and fiberglass. Choosing between these two often comes down to your specific needs and budget. Stainless steel grating is known for its durability and corrosion resistance, making it ideal for harsh environments where water and chemicals are present. On the other hand, fiberglass grating is lightweight, slip-resistant, and cost-effective, making it a great option for areas where ease of maintenance is a priority.

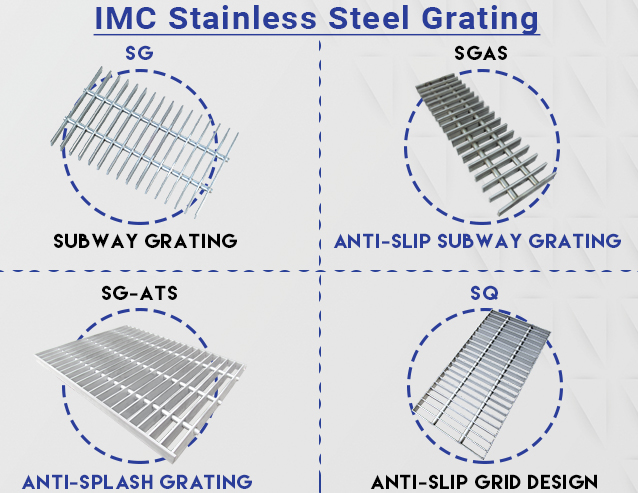

For those leaning towards stainless steel, there are several models to consider. Model #SG is the standard subway grating with 1-inch bar spacing, suitable for most applications. If you're dealing with wet areas that see a lot of foot traffic, Model #SGAS offers an anti-slip surface. For areas with heavy liquid flow, Model #SGAS-ATS provides anti-splash protection thanks to its slanted bars. Lastly, Model #SQ combines an anti-slip surface with a closed grid appearance due to its banded edges. Check out the images below for a visual comparison.

When it comes to ADA compliance, both stainless steel and fiberglass grating options are available. Standard grating has 1-inch spacing between bars, while ADA-compliant grating features ½-inch spacing to accommodate wheelchairs. IMC offers SG-ADA and SQ-ADA for stainless steel and PFG-ADA (blue) and CH-ADA for fiberglass. These comply with ADA standards and ensure accessibility for all users.

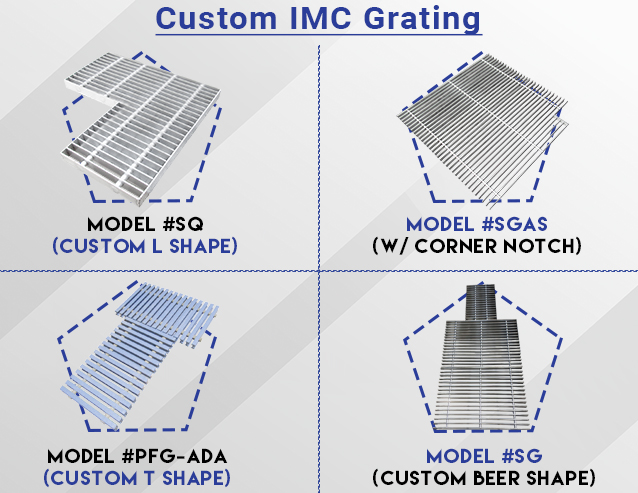

Customization is another strong point for IMC. Whether you need a specific shape or size, we can tailor our grating solutions to fit your exact requirements. Standard grating lengths typically range up to 20 inches, but longer sections can be fabricated if needed—up to 10 feet long and 30 inches wide. Take a look at this example of a custom-sized grating:

Lastly, don’t forget about perforated and louvered grating. These specialty options are designed for aggressive drainage areas and offer uniform drainage respectively. Both are available across our product catalog, so feel free to reach out if you’d like to explore how they could work for your facility.

Grating and floor troughs are essential for maintaining safety and hygiene in any environment. With the right combination, you can ensure a clean, functional space. For more information about our grating offerings, check out our website or contact us directly.

*Disclaimer: The views and opinions expressed in this article are those of IMC/Teddy. Our content is intended for informational purposes only. Please reach out to IMC/Teddy if you wish to feature this post on your site. Thank you!

---

**Social Sharing:**

Share on Facebook | Share on Twitter | Share on LinkedIn | Share on Pinterest

---

Hope this helps clarify things! Feel free to drop any additional questions in the comments below. We’re always here to assist.

Automatic Fire Extinguisher,Automatic Dry Powder Fire Extinguisher,Automatic Fire Ball Extinguisher,Hanging Automatic Fire Extinguisher

Nanjing Txfire International Trade Co., Ltd , https://www.txfireequipment.com