Welcome back to another installment of our monthly FAQ series in 2024! This month, we're diving into the most frequently asked questions about floor trough grating. As always, we’re here to help clarify any doubts you might have.

Grating plays a crucial role in any floor trough system, providing a durable surface that supports foot and vehicle traffic while preventing large debris from clogging the drain. There are numerous options when it comes to choosing the right grating—ranging from materials to designs—which can sometimes feel overwhelming. Don't worry, though—we’re here to guide you through it all.

In this article, we’ll address five of the most common queries about floor trough grating. Let’s kick things off with the first question.

**1. Should I Choose Stainless Steel or Fiberglass Grating?**

This is easily one of the most popular questions we receive. While we’ve written an extensive piece comparing the two materials [click here to read it], let’s break down the key points:

- **Stainless Steel Grating**:

- Non-corrosive and ideal for environments with harsh chemicals or toxins.

- Performs exceptionally well in damp conditions.

- Offers superior strength and longevity, making it a great choice for high-traffic areas with vehicles.

- **Fiberglass Grating**:

- Rust-proof, slip-resistant, and significantly lighter than stainless steel.

- Electrically non-conductive, making it safer for certain industrial settings.

- Easier to clean and maintain, especially in spaces requiring frequent access to the trough beneath.

Ultimately, the decision comes down to your specific needs and budget. Stainless steel may be worth the investment if durability and longevity are priorities, whereas fiberglass offers cost-effective solutions without compromising safety. At IMC, we offer both materials for every floor trough we manufacture.

**2. What Are the Different Types of Stainless Steel Grating, and Which One Is Right for Me?**

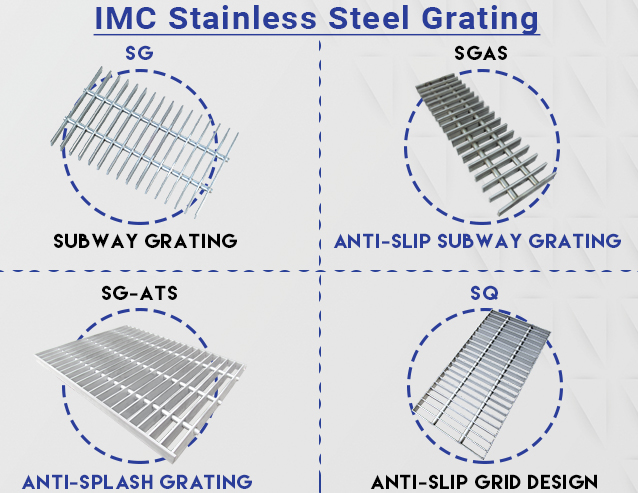

At IMC, we produce four primary types of stainless steel grating, each tailored to different applications:

- **Model #SG**: Our standard subway grating, featuring 1-inch spacing between bars. Ideal for general-purpose use where anti-slip features aren’t necessary.

- **Model #SGAS**: Equipped with an anti-slip surface created through machine serration. Perfect for areas prone to water exposure and heavy foot traffic.

- **Model #SGAS-ATS**: Designed with slanted 90-degree bars to prevent splashback, reducing the risk of slips and falls. Best suited for high-liquid environments like industrial washdown zones.

- **Model #SQ**: Similar to the SGAS model but with additional banding around the edges for a fully enclosed grid appearance. Suitable for spaces requiring enhanced aesthetics alongside functionality.

When selecting the appropriate type, consider factors such as expected water flow and pedestrian density. For instance, if your facility experiences heavy rainfall or frequent water spills, opting for anti-slip or splash-resistant grating would be wise. Conversely, regular grating suffices in drier settings.

Here's a visual representation of the four stainless steel grating varieties:

**3. My Facility Needs to Comply with ADA Regulations—Which Grating Fits the Bill?**

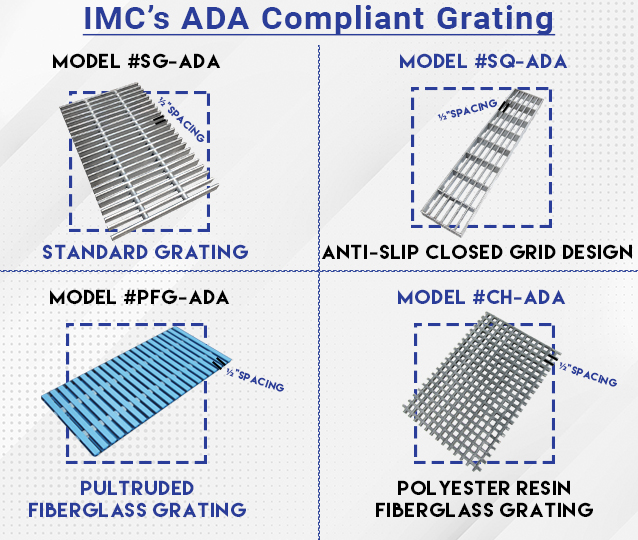

For facilities subject to ADA compliance, both stainless steel and fiberglass gratings are available in ADA-compliant versions. Regular grating typically has 1-inch bar spacing, whereas ADA-compliant grating features narrower ½-inch spacing to avoid catching wheelchair wheels.

IMC offers several ADA-compliant options, including the **SG-ADA**, **SQ-ADA** for stainless steel, and **PFG-ADA** (blue) and **CH-ADA** for fiberglass. Depending on your preferences and operational requirements, these models ensure accessibility while maintaining safety standards.

Take a look at our ADA-compliant grating examples here:

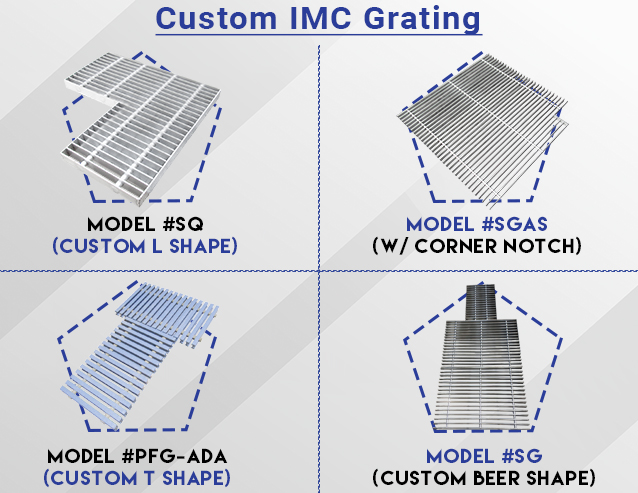

**4. Can You Create Custom Shapes and Sizes?**

Absolutely! IMC specializes in crafting gratings in virtually any shape or size. While standard grating lengths max out at 20 inches, larger troughs often require multiple sections. We can fabricate gratings exceeding 10 feet in length and 30 inches in width to accommodate expansive surfaces. Below is an illustration of one of our custom-sized grating projects:

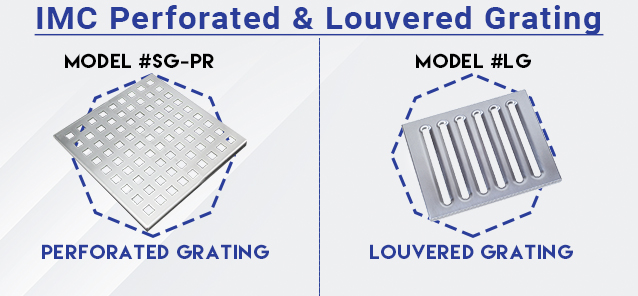

**5. What About Perforated and Louvered Grating?**

In addition to traditional designs, IMC also produces specialty perforated and louvered stainless steel gratings. Perforated grating consists of bands forming ½-inch square holes, designed for high-drainage zones. Louvered grating, on the other hand, features die-formed slots for more uniform water flow.

These specialized gratings are available across our entire product range. Reach out to us for further details if either option aligns with your needs. Here’s how they compare visually:

Grating and floor troughs go hand-in-hand in ensuring safety and hygiene. Choosing the perfect combination is essential for creating secure and hygienic environments. To explore more about IMC’s grating offerings, click [here].

---

*Disclaimer: The opinions and information shared in this article represent the perspectives of IMC/Teddy. Our content is intended solely for educational purposes. If you wish to share this post on your website, please contact us directly. Thank you.*

---

**Sharing Options:**

Feel free to share this post on Facebook, Twitter, LinkedIn, or Pinterest. Let’s spread knowledge together!

Portable Wet Chemical Fire Extinguisher

Portable Wet Chemical Fire Extinguisher,Wet Chemical Fire Extinguisher,Wet Chemical Extinguisher,Wet Chemical Extinguishing Agent

Nanjing Txfire International Trade Co., Ltd , https://www.txfireequipment.com